Grey January times. Grey and cold. Blah, grey, and cold. Which means...

Times to fix and repair stuff. And hack!

Today's project: Vixen/GoToStar upgrade.

I (still) want to build an extension cable for the IDEA (iOptron) GoToStar system. The coiled cable between the hand controller and mount is too short, even when working at the telescope. Today, I thought, let's test that in fact it will work at all. Possibly the longer run of wire would still not function...

But first we have to go back in time. For this project started (like many of mine) a while ago.

Previously, I had picked up some 6-conductor Registered Jack extension or patch male-to-male cables. A pair, I believe; one of which now lives at the RASC Toronto Centre Carr Astronomical Observatory, for the Optec TCF-S focuser.

I also procured some 6-wire couplers, female-to-female. Again, one of these was re-purposed for the CAO custom Optec cable.

Don't remember when exactly, last summer I think, excited, I hooked up the extension cable and coupler between the mount and hand controller. And it didn't work.

Damn lucky now, looking back, that I didn't blow up anything! I know that's happened to other people using the wrong cable or the wrong port.

I knew the mount motors and controller were still fine; I had immediately run the system in a normal configuration after the failed extension cable test. Whew.

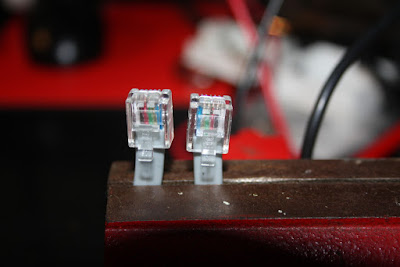

It was then that I noted the wiring configuration of the RJ cable. It was flipped. In ethernet scenarios, these are called "rollover" cables.

My extension cable would need to be a straight-through. So, that was the plan, on this grey day: coddle together all the various pieces to conduct a straight-thru wire test.

Pulled the Vixen mount bag off the shelf. Verified I had all the needed parts: mount proper, GoToStar motors installed, GoToStar hand controller, two coiled motor/controller cables, AC power supply (two pieces). Check.

Looked through various electronic repair boxes and bins to collect all the bits and bobs, in particular, the rollover cable and a coupler. Check.

I also considered other parts for testing. I found a second 6-wire coupler (still in the box)—just in case. Huh. I found a Steren 6-wire surface-mount (telephone) jack (still in the bag)—would be very handy for jumpering. And, curiously, I found a component for a 6-wire coupler: the female jack pin assembly. This was probably from the Optec cable project. Again this would be helpful for jumpering. Check.

Stripped the leads on the female pin assembly. Clamped the assembly to one end of the extension cable. Only way I was able to get a stable configuration was with the assembly in the direction opposite normal. Heh. I realised that immediately flipped the wiring profile. Attached different coloured alligator clip jumpers. Plugged a GoToStar coiled cable into the surface-mount jack. Then, in a brainwave, coupled the two open ends together! They'd be one-to-one! Finally, with the Micronta digital multi-meter set in audible continuity mode, I mapped the wires. I was not completely surprised to see the same colour alligator to the surface-mount tabs.

One last configuration check with the multi-meter, coupler removed, checking each pin, left to right. Perfect correspondence, just like the stock coiled cable. Good to go.

Configured the Vixen mount on the desk. Interconnected the motors with one coiled cable. Plugged the coiled cable from the new tested extension into the mount. Plugged the other end of the extension into the hand controller. Plugged the power supply into the power bar.

Hey! Never noticed that before! Through the seam in the adapter casing, I could see a green LED. A visual verification it was working OK. Plugged the power cord into the mount. As usual, the red LED on the mount illuminated. OK. Here we go...

Powered up the mount. LED switched from red to green. Hand controller? Nominal display!

Tested slewing. It worked.

After setting the date and (an evening) time, I put the mount through a quick one-star alignment. When it completely successfully, the mount started tracking.

Yes!

Test complete. The new, long, grey, RJ extension cable will work. As long as it is configured straight-through.

So, now I need to noodle on doing that...

Do I hack the cable? Or do I hack a coupler? Or something else?

I have a crimper tool but no "empty" 6-conductor jacks; lots of ethernet 8C ones of course. So if I want to use a standard coupler and a "special" cable, I'll need to get a new jack, cut an end off, remap the wires (which will be a bit fiddly), and crimp. Those jacks are a little unusual. Probably will have to go to Sayal or Digi-key...

I could rewire a coupler. That I could do immediately. Earlier I popped open the beige one. It'd be pretty easy to do although it's cramped quarters inside the coupler. Then the cable can be used as is. Mark the coupler as special and good to go. Very compact solution.

Now. The surface-mount plug. That's interesting. Very interesting. If I had another one, I could very easily make a mapped coupler, with lots of breathing room. It would be a bit bulky but it shouldn't really matter. This custom coupler would attach to the mount base or tripod, out of the way.

Not sure why but I'm attracted to this last idea the most... Somehow seems the easiest and fairly fast. Non-invasive? But I will need to buy another jack. Friday? Will the store formerly known as Radio Shack still carry these items?

§

I'm considering drilling a small hole in the AC adapter casing so to better see the power LED. A little risky. Then again it is not really needed. Once connected to the mount, one knows... Lastly, the green, if exposed, might create a new problem. Better leave it alone.

While testing the hand controller operation, I tried the on-board light option. Right. Bright white LED out the front of the hand controller! Which will undoubtedly cause a riot of crazed, frothing astronomers. I will need to change that to red. A quick fix is to cover it with a small bit of red film... Done!

And I just remembered the on-board battery inside the hand controller is dead. Maybe I get a new battery and while opened change the white LED out.

Also found the red film over the mount indicator askew. Finally removed the painter's tape. Fixed it by recutting the piece and fastening down with clear tape.

Identified the AC power pieces. Labeled the AC adapter and its affixed cord; labeled the detachable mains cord as well.

§

Duh. If I had turned over the AC adapter, I would have seen the LED! OK then. Promptly covered the green emitter with a little piece of red film.

Tuesday, January 19, 2016

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment